Building Our Cockpit Doors: The Exciting Start! (MJ Sailing - Ep 336)

Today we delve into the exciting realm of building custom fiberglass cockpit doors for boats. The MJ Sailing team takes us through the meticulous process, from start to finish, as they create their unique boat doors. This comprehensive guide will walk you through each step with detailed explanations and demonstrations.

The Starting Point

With 1 and a half inch thick Nidore as the base material, the team showcases a plastic honeycomb interior, thermally bonded with a scrim fabric. This combination explains its density and strength. They plan to use two layers of 1708 fiberglass skin on either side.

Process Overview

To start, the team cuts down a 4×8 sheet of Nidore to the proper door size using a Bosch track saw for precision. Multiple layers of fiberglass are then layered and glassed together. A unidirectional fiberglass is used in key areas for added strength and rigidity.

Techniques & Tips

The alternative to their current approach would be making molds for each door, which could result in a better finish. However, given the uniqueness of each door and the effort required for molding, they opt for the more practical method.

Primers & Preparations

To ensure a smooth surface, layers of peel ply and cloth to soak up extra resin are used before vacuum bagging. Once the doors reach a rock-hard state, they’re cut down to final size, decor elements added with unidirectional fiberglass.

Challenges & Solutions

A challenge arises when attempting to reach areas above peaks. The team discusses possibly rolling on primer rather than spraying for more precise application. Additionally, planning for window placement and door hinges is key for a seamless finish.

Conclusion

With primer now applied to the exterior cabin sides, the team acknowledges there will be more work ahead, such as covering windows and finalizing door installations. Each step, from cutting and layering to decorating, brings them closer to achieving custom-fit cockpit doors.

One new project we have started though is our cockpit doors! Since we have no seating running along the sill of our cockpit, that entire space will eventually open up. Which means we need to make three separate doors to close it up at times. Two that will slide into pockets next to the cockpit seats, and one in the center which will lift up and latch to the cabin top.

Starting out with fresh sheets of 4x8 nidacore, Matt cuts them down to size, and we go about glassing both sides of them. Each side gets 0.75 oz of chop strand, and then two layers of a 45/45 biaxel.

For extra strength around the edges, Matt will be fitting in pieces made from layers of our unidirectional fiberglass. Matt firstly layers six sheets of our unidirectional, cuts them to size, then de-cores the edges around the doors and bonds in the pieces of cured unidirectional by using our TotalBoat structural putty.

In some other fun news, we get the chance to prime another area for the first time. Our cabin sides and the under the cabin top. Although the exterior sides of the cabin will be covered by glass or acrylic, we still wanted a fairly smooth surface for those to bond to. And since the underside of the cabin can be seen any time you're sitting on deck, yeah, we just want that to look good, haha.

Hopefully these steps will let us get into close up shape pretty soon! Once we move out of the tent and into the work yard, we can begin attaching the nose cones and stern to finally reach the full length of our catamaran!

We hope you enjoy!

Building Our Cockpit Doors: The Exciting Start! (MJ Sailing - Ep 336) Locations

- The episode does not mention a specific location with coordinates. The content focuses on the process of building custom fiberglass cockpit doors onboard the MJ Sailing team's catamaran. (0,0)

Note of Recognition for MJ Sailing

At WeBoating.com, we profoundly acknowledge the unwavering dedication that MJ Sailing and other creators invests in crafting each and every video. Their passion for delivering exceptional content shines through every frame, and it's a labor of love that deserves your attention.

We invite you to watch their captivating videos and actively engage with their content, including their social media links above. Liking, commenting, and sharing their work goes a long way in fueling their creative fire.

We're also inviting you to explore any sponsorships and partnerships highlighted in the video description of "Building Our Cockpit Doors: The Exciting Start! (MJ Sailing - Ep 336)", or directly on YouTube. By considering their offerings or purchasing services and items, you not only support MJ Sailing but also the brands and collaborators they're associated with.

If you have any feedback, corrections, or additional information about MJ Sailing or their videos, please use the comment form below to share your thoughts with us.

Thank you for being a part of our community and supporting the creators we cherish. Your time and support truly matter!

MJ Sailing Lastest Videos

Raw Fiberglass ➝ Finished Cabinet (Boat Build Transformation!)

Turning this cabinet from raw fiberglass into a finished, painted space took more steps than it looks: sand, wipe down, TotalFair skim, primer, and topcoat. Not perfect… but it definitely passes the five-foot rule 😅⚓️ Full episode: MJ Sailing – ...

Six Layers of Fiberglass and Zero Regrets (MJ Sailing – Episode 372)

Overbuilding the engine bed might seem excessive… until you factor in weight, torque, vibration, and a moving ocean. In this episode, we lift and align our diesel engine, temporarily set it in place, then pull it back out so Matt can glass the engine m...

One Diesel Engine, One VERY Tight Space!! (MJ Sailing – Episode 371)

Six hundred pounds. Inches of clearance. And absolutely no room for mistakes. Now that the engine is finally inside the cockpit, the next challenge is getting it the rest of the way into the boat — and this part might be even harder than the lift itself...

Diesel Engine Lift on a Catamaran – With EXTREMELY Tight Clearances (MJ Sailing – Episode 370)

When heavy equipment meets tight clearances, things get interesting fast. This episode is one of those moments where everything slows down, everyone’s watching closely, and every single inch matters. We’re getting our diesel hybrid engine off the grou...

Winter Boat Projects Don’t Wait for Spring

When winter shows up, the build doesn’t slow down—it just gets… creative. With the cockpit shrink-wrapped, a single zippered doorway as our gateway to the cold, and our diesel heater pushing warm air wherever we need it, we’re keeping this project...

She Drills Holes, He Fills Them (MJ Sailing – Episode 369)

This week’s episode jumps right into the fun stuff—Jessica’s back in the engine bay, drilling out two new holes in the starboard engine bed for a pair of thru-hulls we’ll be installing. It’s one of those jobs that sounds simple until you’re dan...

This is the END!! Of Sanding Season. (MJ Sailing – Episode 368)

This week’s episode is a mix of random projects we’ve been tackling around the boat all summer — the kind that never quite fit into any other video but still show the day-to-day progress of the build. We’re checking in on the helm station, which h...

Aligning the Longeron & Forebeam on our Homebuilt Catamaran (MJ Sailing – Ep 367)

After weeks of sanding and fairing (the least glamorous part of boatbuilding), we finally get to do something exciting — bringing the bows of our catamaran together! The longeron and forebeam are two critical pieces that tie the front of the boat into s...

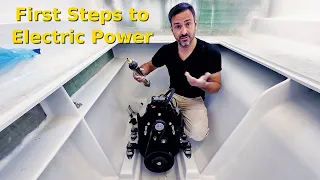

Installing Our Electric Motor System | Milling, Mounts & First Fitting (MJ Sailing – Ep 366)

We’re officially kicking off the installation of our electric drive system! ⚡️ Back in the spring, we received our electric motor, but we couldn’t move forward with fittings until our couplers were milled to the proper size. With that step now com...

Getting Ready to Install Our FIRST EVER AC!! (MJ Sailing – Ep 365)

Can you believe we're finally getting to the install part of our build?? Although, since most things won't get permanently mounted until the end, I guess we could call this a fitting, haha. This week we prepare for the install of our 9k BTU AC unit from M...

Building Our Custom Helm Seat – Foam, Glass & Vacuum Bagging (MJ Sailing – Ep 364)

This week, we’re diving into a project that’s been quietly taking shape in the background: building our helm seat from scratch. While it might seem like a small piece of the boat, it plays a major role in both comfort and functionality—so we wanted ...

Diesel Demands Space, Electric Plays Nice (MJ Sailing – Ep 363)

We’re back in the engine bays this week, continuing to prep both sides of the catamaran for our twin propulsion systems—an electric motor in the starboard hull and a diesel-electric hybrid in the port hull. After receiving our full system from Hybrid ...

Making Room for 300 Pounds of Power (MJ Sailing – Ep 362)

We're prepping our catamaran engine beds for a brand-new hybrid propulsion system—an electric motor in one hull, and a 300+ pound diesel-electric hybrid in the other. In this episode, we tackle fiberglass reinforcements, fairing work, and reveal how we p...

Glassing on our Catamaran Bows – After I Clean Up a TOUGH MISTAKE (MJ Sailing – Ep 361)

Get a FREE pair of crew socks with your 100% waterproof Vessi shoes! https://crrnt.app/VESSI/y6920bP9 We’ve got both bows bonded onto our catamaran now, but before we can start glassing them in place, we run into a tough—and time-consuming—setback. ...

WE SCREWED UP Last Time. Here’s How We Fixed Our Custom Catamaran Build (MJ Sailing – Ep 360)

Go to https://nordvpn.com/mjsailing to get 4 extra months on a 2-year plan!! Just use code MJSAILING A huge thanks to this video's sponsor NordVPN. ALL PROCEEDS go directly to materials for custom build catamaran. This week we once again try bonding a b...

EXTENDING Our Custom Build Catamaran by THREE FEET! (MJ Sailing – Ep 359)

Get 15% off your data plan for Saily by using code MJSAILING. Follow this link: https://saily.com/mjsailing We’ve waited years to attach the bows—and one wrong move could ruin it. Watch as we finally take the leap to bond them on. We're so happy the ...

CATAMARAN BUILD – Picking Interior Paint For Our Boat (MJ Sailing – Ep 357)

Get your hands on THE BOOK: The Ultimate Guide to Rebuilding a Civilization Use code MJSAILING10 (10% discount, valid 1 month) https://mdsh.io/e2hrx7340f thebook #howtorebuildcivilization #hungryminds I'm so happy to tell you that we're 5/6ths of the way ...

Catamaran Build – SUIT UP TO STRIP DOWN!! (MJ Sailing – Ep 357)

Use code MJSAILING at the link below to get an exclusive 60% off an annual Incogni plan: https://incogni.com/mjsailing We're at Stage 4 of painting, which means more work on the bridge deck! Because of the tight spaces and the hose of pressure/air that f...

We Have Our Hybrid Engine – HOW DO WE INSTALL IT?!?!(MJ Sailing – Ep 356)

Click the links below and use my code 25EFSMMJSA for an extra 5% off @EcoFlowTech WAVE 3 and GLACIER Classic. (The code is valid until May 25 and cannot be combined with other coupons). Get a free 110W solar panel with your WAVE 3 order(From April 25 to...

CATAMARAN BUILD: It’s Really Happening – Interior Paint Begins After 3 YEARS (MJ Sailing – Ep 355)

Click the links below for an exclusive discount on the @EcoFlowTech GLACIER Classic from April 18 to April 24! Pay $100 and get $300 off the GLACIER Classic. (The coupons can be redeemed between April 25 and May 25). EcoFlow GLACIER Classic: https://bit....

CATAMARAN BUILD: From Seams to Smooth – Cabin Top Progress Continues

From three pieces into one, we're now continuing work on our cabin top. A coat of primer brings our cabin top seams closer to disappearing—plus adds vital UV protection to the fairing work beneath. In this week's video we turn to work on the exterior an...

OH GLORIOUS SANDING!! All The Tools We Use to Get the Job Done (MJ Sailing – Ep 353)

Last chance to enjoy the Early Bird Deal for Everfrost 2: Pay $10 now to save $300 later, plus get a free gift: https://ankerfast.club/jmsb9o #AnkerSOLIX #Everfrost2 #electriccooler #outdoorfridge #campingfridge Once again we apologize for the silence thr...

Why You Haven’t Heard From Us the Past Month (MJ Sailing – Ep 352)

Temperatures dip well below freezing as we try to stay warm aboard our 31' liveaboard boat during our off hours, and we work hard to keep the catamaran at a minimum of 55 degrees so we can continue to work through the cold. We wish we had a more interest...